| Lee "Classic Reloader" / .38spec | |||||||||

|

click on an image

| Reloading... I enjoy reloading my centerfire cartridges, both handgun and rifle.

I started some 10-12 years ago and I estimate that I've reloaded

some 25-30,000 cartridges, mostly 9mm and .223 calibers.

There is always something else to consider and learn about

internal ballistics, cartridges and firearms.

I still have my eye-sight, hearing and fingers, so I've been

careful thus far and hope to continue.

enjoy, and do be careful | ||||||||

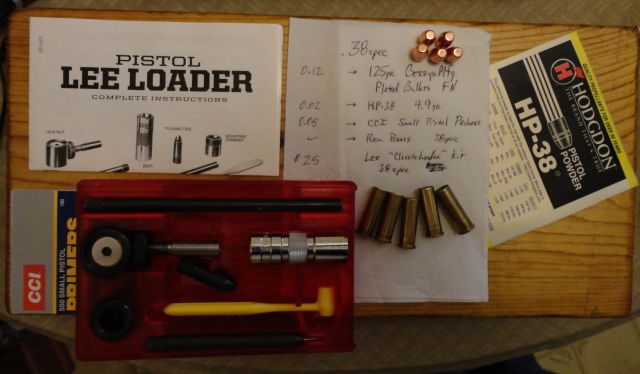

| The basics that will be needed:

a) spent brass cases for the reloadable caliber b) fresh primers for the reload c) adequate propellant (aka: gun powder) for the "charge" d) proper bullets e) and some basic tools ... prior experience and knowledge are not 'optional' a rough cost-estimate puts a .38spec cartridge

| ||||||||

| We begin by removing the spent primer. The decapping pin will insert thru the case to "punch out" the spent primer. A modest tap or two with a small hammer should be enough. | |||||||||

| Once the primer is removed, the primer-pocket should be cleaned to remove the ash/crud to permit a new primer to seat properly and be able to ignite the powder thoroughly. If you do not have the 'cool-tool', a simple small flat screwdriver will get the job done. | ||||||||

| Clean the Brass | Not shown with a photo, but at this point, the brass should be

cleaned. Many reloading instructions will suggest use of a

"tumbler" to clean/polish the brass... we can

do just fine with a small plastic jar/lid and some warm soapy

water and shake it for several minutes... rinse/repeat a time

or two. The goal is to rid the brass of dirt, grime, ash and

any crud that could cause the movement of the brass to be

compromised as it goes thru the reloading dies(equip) and

then the Magazine and firearm.

Insure that the brass is TOTALLY DRY before proceeding.

I will often let mine dry for a day or two, if necessary.

You do not want ANY humidity in your cases as you proceed

to inserting a fresh primer or powder.

Reloading Die sets will often refer to a 'carbide sizing die'

for handgun sizing operations,

so the brass DOES NOT NEED LUBRICATION.

| ||||||||

| The spent brass case needs to be ReSized DOWN to a

specification for reuse. This entails forcing it into

a "die" that will squeeze the brass to a desired size.

DO NOT strike the Lee "Classic" die body with a steel hammer,

I will use a small block of wood to soften the strikes with

hammer to drive the brass into the die body.

A VERY-MODEST amount of "sizing lubricant" should be

used to help the brass to slide in/out of the sizing die.

I DO NOT squeeze the tube, I merely wiped my index finger along

the vaseline-tube neck and got a tiny-bit of it on my finger

to lube all five of these demo cases.

Think about the 16-year olds on their first date, they want to be ready for a (maybe) good night kiss... and will very lightly apply some "chap-stick" to their lips, to be careful to NOT have dry/chapped lips and at the same time to NOT be oily/greasy !! The same applies to sizing-lube !! just barely enough to help the brass ease in/out of the die, without any excess. Just an "oily/slick" feeling to the brass. | |||||||||

| The brass should be all the way IN, flush with the bottom of the die-body. | ||||||||

| I will deviate from the Lee "instructions" at this step. They will insert a new primer, but I prefer to remove the brass, check that it has sized properly and apply a slight flare to the case-mouth ... THEN insert a new primer. I do not think their instructions are "wrong".. just this is how I prefer to do it. | |||||||||

| The 'priming rod' is used to drive-out the sized brass from the die-body. | ||||||||

| Use the decapping-base to catch the brass case as it comes out. | ||||||||

| Will the ReSized case insert into the firearm cylinder (chamber)?

Easily? Will it drop-out without pressing the stem? | ||||||||

| A sized-case typically does NOT let a new bullet insert easily. They tend to be the same size... D'oh. Using a flaring tool, the case mouth can be just slightly flared-out, to permit the new bullet to be seated into the case. | |||||||||

| Just a modest strike should do it. | ||||||||

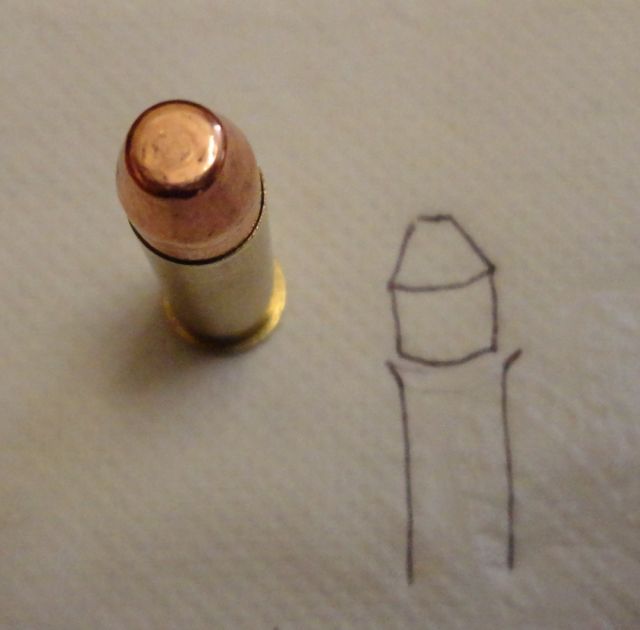

| The sketch is exaggerated. Like applying sizing-lube, just enough flare, but not more than is needed. If you can "see" the case mouth flare, it is likely TOO MUCH. Proceed slowly and notice how the new bullet will find a stable resting place... then no more flaring is needed. | ||||||||

| Have a fresh primer, ready to be inserted into your cleaned, sized, flared brass-case. | |||||||||

| Place the primer onto the center-support of the priming chamber.

Notice that the chrome ring (washer) is spring-loaded and will

recess to permit the brass to be pushed DOWN onto the primer.

It only goes down enough for a thorough seating of the primer.

Properly seated primers are Flush-to-slightly-recessed from the brass base (called the 'head') | ||||||||

| Place the brass-case onto the primer (you'll likely have to hold it, it may not rest by itself) | ||||||||

| Place the die-body over the brass with the primer-rod going down to the bottom of the case. A light tap of the primer-rod will begin the insertion of the new primer into the primer-pocket. | ||||||||

| A partially inserted primer.

Check that it is properly aligned and not going to go in sideways or in any way mis-aligned. | ||||||||

| Removing the die-body and using a glove (just in case),

continue to tap the brass-case ONTO the new primer until it is

properly seated.

The only time I've had a primer detonate.. was at this step, the primer was inserting crooked and I did not know it... So after that... I modified my technique to start/ INSPECT/ then proceed to seat the primer... There was no injury or damage... it was LOUD !! and startled me. I did take a break to relax and get a change of underwear ~~grin | ||||||||

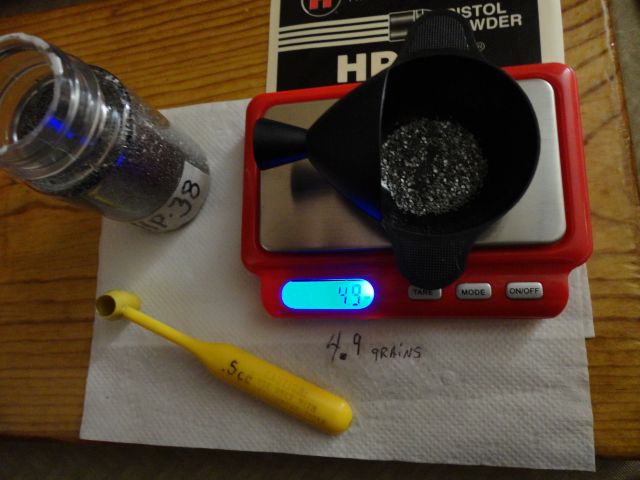

| The Lee "Classic" loader kit provides one of their little

Yellow Powder Dippers™ that is appropriate for the

caliber being reloaded.

Over time, using Lee die sets, I have a modest collection of the dippers, in a variety of capacities (... 0.5cc ... 1.0, 2.0, etc). I prefer to dispense powder with a calibrated powder-drop. Using dippers is a skill that can be learned with a little effort. DO NOT expect to just scoop-up some powder and be precise to the exact amount of powder needed ! (see video link -below- that shows how to "dip") I will take the dipper-size that I need and the selected powder (they each have different densities ! ) and I will practice with my scale until I am confident that I can "dip good" ! It takes several dip-sessions of several dips to "get it". When the caliber, bullet, powder change... so does the charge, so, powder-dipping needs to be checked against a good powder scale (reading to the nearest 0.1 grain... 7000 grains is a pound) With a scale and a zeroed-pan, dip TEN times into the pan,

did you get 10x the weight you wanted ?

| |||||||||

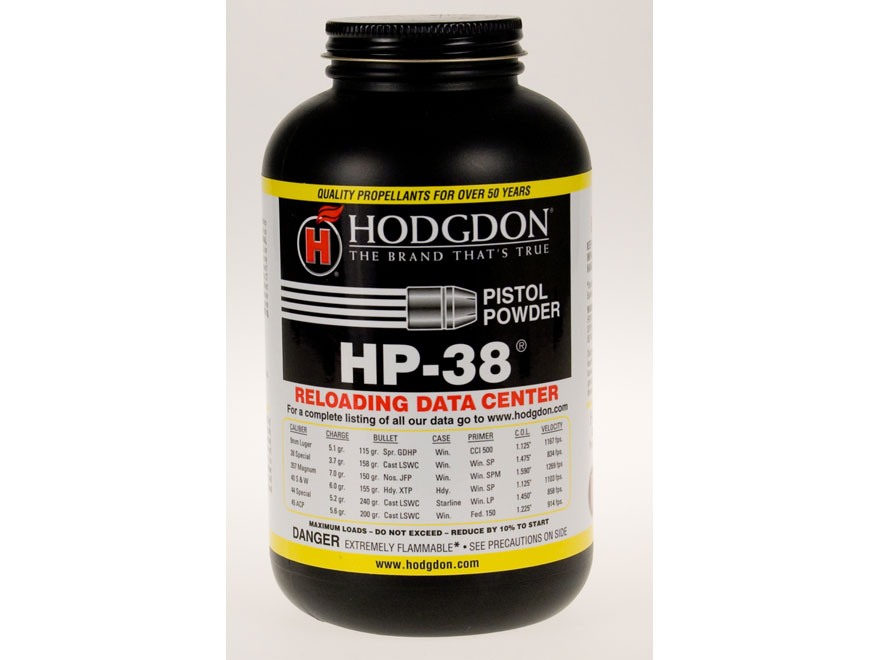

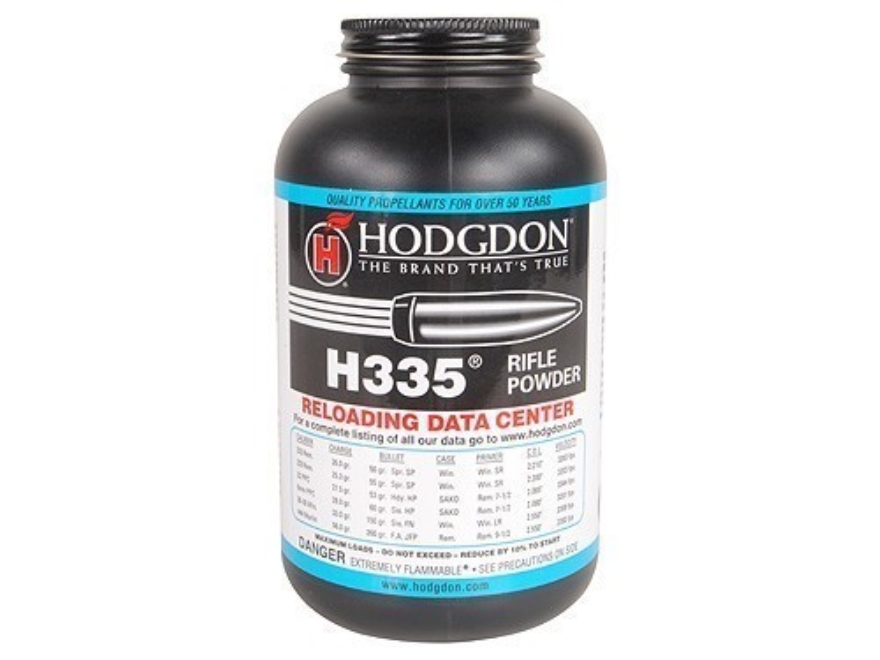

| an online

Basic Data Manual by Hodgdon Powder |

Propellants have burn characteristics that are well designed

and well produced for particular cartridges, firearms and use.

DO NOT ASSUME that you can just add-a-little-more-powder and

make your bullets go faster... Turns out that the

burn-characteristics are much more dependant

on PRESSURE than on the amount of propellant !

Adding a little more powder removes some of the case-volume and thus skews the pressure as the powder burns. There is a pressure range where the powder can perform as it is designed and this is reflected in the "load manuals" (of which you should have a few: Lee, Speer, Lyman, Hornady, Sierra, Nosler, Barnes and others). They will provide a range of powder to be used with a particular bullet in a particular cartridge... Stay IN THIS RANGE !! The burn characteristics are NOT linear (intuitively predictable) and the burn gets squirrly when the pressures are not obtained as designed. Just because you did not blow yourself up tossing pure-Sodium-pellets into a water filled trash can when you were in college... does NOT mean you won't do it experimenting with propellants... | ||||||||

| Dipping without a scale can be risky... this scale is by MtM and costs about $35, other brands/models compete with it. | ||||||||

| As you place your powder into the case(s), examine the contents, look for charges that are MISSING or TOO-MUCH... you may not visually measure to the 0.1gr... but learn to look for those powder amounts that are a mistake !! | ||||||||

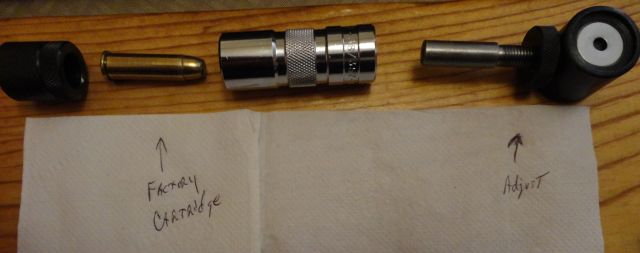

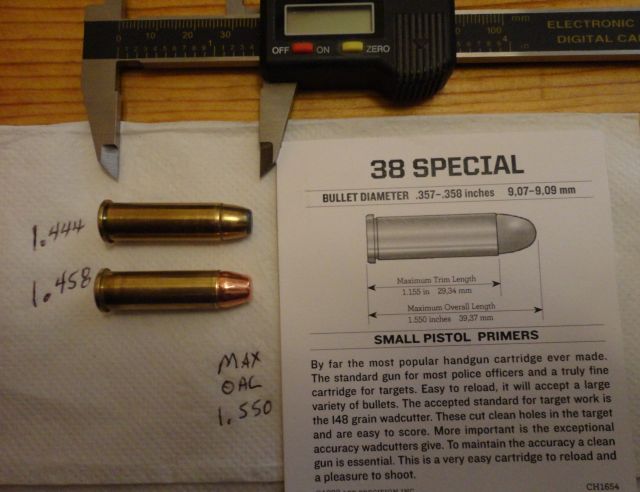

| The Lee "Classic" kit provides for a bullet seating adjustment.

The seating-stem screws into the priming-chamber with a lock-nut.

We can adjust the seating-settings to fit a factory cartridge and then seat our new bullets to provide a "copy cartridge". Using the Decapping-Base... Die Body... Stem... with a "Factory cartridge" that we know works well in our firearm and has a similar bullet 'ogive' (aka shape)... Place your factory cartridge into the Decapping-Base and put the die body over it. Adjust the lock-nut and seating-stem to "just come together"... and tighten the lock-nut. This will seat a new bullet into the case and provide the same OAL (aka OverAll Length ) of the cartridge. | |||||||||

| Insure that you have a well-seated primer and a proper powder charge in your case and ready with a new bullet. | ||||||||

| The seating-stem will be too-high as the amount we need to seat... tapping the primer-chamber will press the bullet into the case. The lock-nut will rest on the die-body to stop the seating at our desired depth... | ||||||||

| Bullet seated... no more gap. | ||||||||

| the "factory cartridge" (left) and the ReLoad (right) look pretty close to the same. | ||||||||

| We can measure the OAL (Over All Length) with a caliper... You DO NOT want to exceed the MAX-OAL, the cartridge will likely NOT function/chamber in your firearm. | ||||||||

| Don't have a caliper? Just see if the cartridges will

easily drop IN/OUT of the cylinder (chamber) of your firearm.

The ReLoad is on the right, Factory on the left... | ||||||||

| Do they each drop IN/OUT the same way... no obstructions? | ||||||||

| Crimping | Opinions and advice will differ... as to if/when/howMuch to crimp...

It is my suggestion that you give a modest crimp to ALL cartridges, Pistol, Revolver, Rifle, semi-auto, straight-walled-brass, rimmed and shouldered... Have knowledge, experience and reasons to NOT crimp... rather than wait to have a reason TO CRIMP. Cartridges "chamber" ( fit) as they come to rest on/against something... It may be the 'rim' (.38spec, .30-30win) or the cartridge shoulder ( .223rem, .308win, .30-06sprg), or the case-mouth resting on a ridge in the chamber ( 9mm, .40sw, .45acp ) ... Keep this in mind when crimping your "acp" cartridges! You do not want the OAL of your cartridge to change...

| ||||||||

| the .38spec die body has a crimp-ridge in the TOP of the body.

Examine the opening... that ridge will push the case mouth into the bullet, to form a crimp. | ||||||||

| The die-body is resting on the case rim.

DO NOT drive the die-body all the way down... just a modest smack with your hammer to impress a modest crimp. the visible gap (shown between the die body and base ) will not change... just give a light crimp and stop. all done. | ||||||||

| Check again. Does your ReLoad slip into the cylinder the

same as the factory-cartridge ?

It should NOT EVEN COME CLOSE to sticking out of the front of the cylinder... that inhibits the cylinder rotation and lock-up (aligning the cylinder with the barrel !! ). | ||||||||

| done. | that's the general idea... repeat as needed, for each cartridge. | ||||||||

| for each brass-case:

a) de-prime and clean each case b) re-size the brass c) flare the case mouth d) insert a new primer e) drop the right volume of the right powder f) seat the correct bullet to the correct depth g) crimp the bullet into place h) check, inspect, measure, double-check along the way. | ||||||||

| five spent cases are ready to go again... | ||||||||

| head back to the range to make some more "empties" | ||||||||

| /\/\/\/\/\ | |||||||||

| Here's a YouTube-user that seems to like using the Lee "Classic"

Loader kit...

/\/\/\/\/\

|

|

|

Some inter-related comments on Reloading Brass "preparation"...

| I mentioned having reloaded some 25-30k cartridges in the last decade or so... that may be a lot (or not) to you, depending on YOUR experience and expectations. Dang-near each on of those were done on the little Lee 'Reloader' single stroke aluminum press (costs about $30). I have a larger press that is needed to size the larger Rifle cases... but the seating and crimping steps are done just fine on the little ReLoader Press. This is easily over 100,000 strokes of that little handle ! Each one of those brass cases were handled pretty much as

described above... just the tools and equipment varied to

perform each step in the process.

I decapped each case with the decapping-pin and base

(I wore out one pin, the current one is showing some wear).

I cleaned each primer pocket and thoroughly washed the cases

in hot-sudsy water and rinsed (repeated as desired)...

|

Not to be paranoid, but consider this...

| I started without a tumbler and the washing worked fine for me... so I never felt the need to get one... Then I happend to read one of my "load manuals"... Modern Reloading, 2nd by Richard Lee of Lee Precision, on page 48... I'll quote the paragraph: If using a case tumbler, you should be aware of lead poisoning. John's [Lee's son] shooting companion was diagnosed as having elevated lead in his system. Because he not only shot a great deal at an indoor range, and loaded lead bullets that he cast, it took considerable detective work to find the cause. John supplied him with a lead detection kit for use around his casting equipment and it showed very little. On a hunch, he tested around his case vibrator and found extreme amounts of lead. He said the worst offender is a sifter used to separate the media from the cases. Great clouds of dust are released. The lead comes from the priming compound. Primer manufacturers are trying to get the lead out, but the old stuff will be with us for years to come. Each situation can vary, a lot... but I feel a bit lucky

to have only accidentally used soap/water to wash my

cases and it washed away the primer-residue with it,

and while handling them, I was washing my hands in

sudsy water, too.

|

Another "reloading" thought.

| some time ago, I read an article by Mossad Ayoob (an rare name, but he is a well respected writer and instructor with on the job experience) about firearms, the law and reloaded cartridges. We each want to think about the power and accuracy of hand reloaded cartridges that are specific for our firearm and not that store-bought factory stuff... Well... consider the occasion when you use your firearm for self-defense in the home, traveling or personal carry... If you have your common reloaded target-range cartridges in your firearm... and (God forbid) you end up using that firearm... There is a member of your community that has a JOB to prosecute those CRIMINALS that have to LOAD their OWN BULLETS to use on their victims !! He'd be that "District Atty" that wanted your vote... What Mr.Ayoob suggested is to use a common store-bought

"defense" ammo for your firearm, except at the range

when you can use your reloaded cartridges.

|