|

| More Toys...

|

|

| A (very) minimal list of items to begin

Reloading Straight-Walled Handgun cartridges.

I am making many assumptions to list the following items

to start learning how to reload...

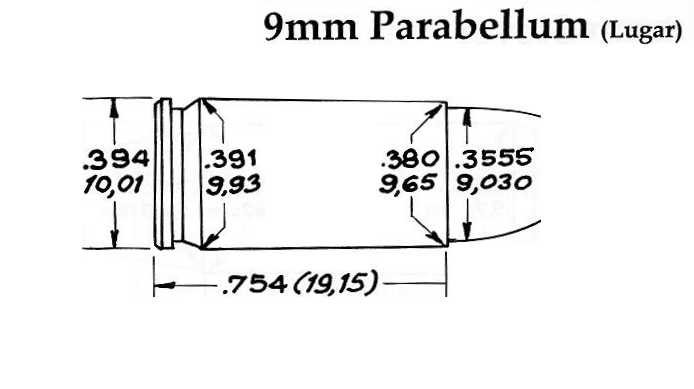

a. 9mm is a common cartridge

b. be able to produce safe, good and usable cartridges

c. be able to acquire additional reloading equip,

as the interest and desire motivate

d. keep initial investment at a minimum

should this not be your next hobby

Get out the popcorn, it's Movie-Time...

A lot of folks have a new hobby "reloading video camera shooting",

They make a lot of Lighting, focus, sound, framing etc

errors in their video... rest assured they are just as

much of a novice with their "reloading" as with their video camera...

but, you get to see the equipment "in action".

A user has posted a 3-part video on YouTube that uses

fairly basic/minimal tools

to demonstrate reloading 9mm:

P1

P2

P3

Free Targets, for:

Pistol

&

Rifle

|

| |

|

|

Pistol-Powder: Hodgdon HP-38

$25 per pound / A very common reloading Pistol-Powder,

burns clean and reasonably "fast burning".

The powder "load" for handguns run approx 5.0gr,

at 7000gr per pound, easily provides over 1000 loads

Best purchased locally, as "hazard material" shipping fees

would apply.

Futhermore, Powder & Primers cannot ship in the same box,

so the Hazard-fees apply to each !!

Hodgdon's webpage for:

Pistol Powders, scroll down for HP-38

HP38 is a spherical powder that is great for low velocity

and mid-range target loads in the .38spec, 9mm, .44spec, and .45acp.

This high energy powder provides economy in loading.

Hodgdon provides an online

Basic Data Manual.

|

|

| Since powder is not sold in containers smaller than One-Pound,

and it provides enough powder for over 1000 "loads",

it only makes sense to get 1000 primers...

|

|

Primers: CCI #500 - Small Pistol

$40 per 1000 / A very common reloading primer for

'small pistol' cartridges.

Primers come in FOUR sizes, be sure to get standard "Small Pistol" primers.

Not: 'Magnum' or 'BenchRest' or LargePistol, LargeRifle or SmallRifle.

They are all different and cannot be substituted.

Other brands exist, too: Remington, Federal, TulAmmo,

Wolf and Winchester...

Best purchased locally, as "hazard material" shipping fees

would apply.

Futhermore, Powder & Primers cannot ship in the same box,

so the Hazard-fees apply to each !!

CCI's webpage for:

Standard Pistol Primers

|

|

| Now that we have Powder and Primers for 1000 reloads,

let's get 1000 bullets...

|

| BerrysMfg Bullets:

9mm HBRN-TP 115gr - CopperWash

$95 for 1000ct (product item #00173)/

A good bullet to begin reloading.

Another source of bullets & Lee Reloading stuff is

Titan, $15 for 100ct, referenced below.

|

|

|

The above items are 'consumable components', in this example,

about $160 per 1000 cartridges reloaded.

Keep a "lab notebook" of your components (date, $$, Lot##, etc)

and what "load" data you use.

This permits you to repeat the ones that work and

avoid the ones that don't.

|

|

|

Next are the One-Time purchase 'reloading tools'.

|

|

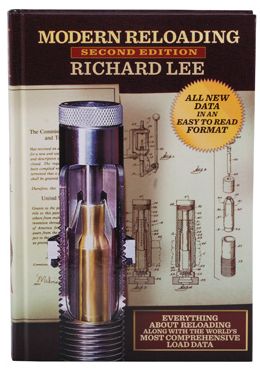

Book:

Richard Lee - Modern Reloading, 2nd

$18 / one of the best "load manuals", first ~125pages are a thorough

explanation of chamber-ballistics and reloading-processes/techniques

and the tools to perform it with more "load data"

than you can shake a stick at...

Lee's webpage for:

Modern Reloading book

Best to confirm "load data" online these days, like:

Hodgdon

|

|

Lee Reloading Press

$28 / an adequate Press for straight-walled pistol brass.

NOT adequate for Rifle brass "sizing".

it needs to be mounted on a small board

(alongside the Powder-Dispenser),

which would be C-clamped to the workbench.

Lee's webpage for:

the Reloader Press

|

|

Lee Carbide 4xDie Set

$43 / A good handgun die set.

Dies: FL-Size, Flare/Powder, Seating, Crimp.

Plus shell-holder for the Ram/Press.

The use of each of these dies (and the RamPrime mentioned below)

will need particular "adjustment" in the press for the

particular caliber, brass and bullet in order to produce

the desired finished cartridge.

You would need another DieSet (~$45) for each Rifle/Pistol

caliber you wanted to reload.

Lee's webpage for:

Pistol 4xDie Sets

|

| Step: 1

Step: 2

Step: 3

Step: 4

Step: 5

| After (1) washing and drying the brass to remove dust, dirt,

grime and crud...

It should be run thru the Sizing-Die to

(2) remove the spent primer and

(3) re-size the brass to the specified diameter.

Clean the crud out of the primer-pocket with a small

flat-bit screwdriver.

The brass is now ready to use the Expander-Flair Die.

This die produces a sleight bell or (4) flairing

to the mouth of the case

in order to allow the bullet to seat evenly.

Once flaired, a (5) new primer can be inserted.

|

|

Lee RamPrime

$11 / This RamPrime gizmo attaches to the press where a die would

be placed. You handle each primer with your finger tips

to get the primer inserted into the Primer-Pocket.

You may soon find that you would prefer using the

Lee Ergo Primer Tool ($28).

You will need a

Primer-shellholder ($3) to hold your brass while the

primer is inserted.

This uses a different-shaped shell-holder from the Ram/Press

shell-holder provided with the Die set.

|

|

| Once the case is flaired and primed, the powder "load"

can be added. Handgun loads are in the range of about 5.0gr

per cartridge. A deviation of some 10% of the specified "load"

is expected to produce a "light" or "heavy" firing, more than

10% deviation can produce un-desirable results (stuck bullet

in the barrel... or too-much stress on the firearm!

|

|

Lee Powder Dispenser

$25 / a basic (but good) powder dispenser.

once calibrated for a particular powder "load",

it will dispense the powder into each prepared case.

it needs to be mounted on a small board (alongside the Press),

which would be C-clamped to the workbench.

Lee's webpage for:

Powder Dispensers

|

|

MtM mini Digital Scale

$40 / powder scales need to measure in 0.1gr resolution.

This digi-scale is extremely 'smart', check out the details

or "get one to see what's inside" (to paraphrase Nancy).

The powder-dispenser must be "calibrated" (adjusted/checked)

to dispense the "exact" amount of powder desired for a "load".

MtM's webpage for the:

DS-750 digital scale

A video on the MtM

DS-750 digital scale

| Step: 6

Step: 7

Step: 8

| Once the Powder-dispenser is calibrated for the desired "load",

drop the powder into five of the cases, visually inspect each

case to insure that they have a proper/equal amount of powder.

With the (6) Seating-Die, a bullet can be pressed into the

brass case to the proper depth.

Almost done.

The (7) Crimp-Die is used as a final step to place

a modest crimp of the brass case onto the bullet.

This insures a good seal of the cartridge for proper

initial pressure as the powder burns. It also helps to

hold the bullet in place when subjected to the

shock of ReCoil to prevent the bullet from moving

in/out of the case.

As a (8) "desk check", field strip your pistol and

remove the barrel.

Compare how easily a Store-bought-factory-cartridge

will slip in/out of the barrel chamber.

Does your reloaded cartridge do the same... ?

Observe very closely the depth at which the cartridge rests

in the chamber, is your ReLoad slightly higher/lower ?

if it is not really-close to the factory-ammo,

it may be poorly done and cause mis-feeds.

| |

|

The above items are adequate to reload perfectly usable cartridges.

I would consider this a 'starter set',

as other tools are desirable to insure easier/precise reloading.

However, to take the first-step

and be able to produce good cartridges this will do it.

If another handgun caliber is desired, just add $50

for the 4xDieSet for each caliber:

.38, .44, .45, ... etc.

Again, above is for Straight-walled Pistol cartridge reloading.

Rifle reloading presents additional equipment

and handling considerations.

| | |

| |

|

If my quick-math is close...

$160 for 1000-round consumables

$150 for basic tools

How much would 1000 rounds of your ammo cost ?

... and you still have the tools !!

the next 1000 reloads will cost $160

| | |

| |

| many more accessories and tools exist, depending upon the

desires and problems encountered.

As a beginning Reloader, seriously consider using

Remington™ ammunition and saving the brass for reloading.

Remington brass alloy resizes easily and has a well-formed

primer-pocket that makes cleaning and insertion of the new

primer a breeze, while many other brands present some

minor/frustrating obstacles.

Do not proceed to place an order for any of this equipment

just because it is listed here.

There are MANY aspects to to be discussed/described that

are too voluminous to type in a few words...

Alternate equipment choices exist, too.

Use this list as a 'discussion' check-list.

Click on the links (item description) to view the

product pricing, avail, detail description

with Feedback/Reviews ... at

MidwayUSA.com

All Lee products and some component-bullets can be

purchased via

Titan Reloading, in WI.

Good luck

and try not to become the next nominee for a 'Darwin Award'...

(paraphrased from the Lee 9mm die-set instructions)

1. Prepare Your Cases

Discard cases with defects such as split necks, indications of

head separation or anything that would make them unsuitable for

reloading. If you do not have the carbide sizer, this is a

good time to lube your cases. Use lube very sparingly.

2. Full Length Sizer

Screw the full length sizer in until it touches the shell holder

and tighten the lock ring finger tight. The decapper is retained

by a collet. Should it be overstressed by an obstruction;

it simply slides up without damage.

3. Expander Die

Screw the die in until it touches the shell holder,

back out one turn. Finger tighten the lock ring.

Screw the die in until flare is to your liking.

For maximum case life, flare only enough to easily

accept a bullet. In use, the expander plug travels approximately

3/8" wighin the die and comes to an abrupt stop

at extraction. This helps the[sic] shake the powder through.

However, we recommend you check to be sure all the powder has

cleared the funnel and expander plug.

Be sure to occasionally clean the bullet lube from the

expander plug to prevent a powder clog.

4. Charge the Case

Select a load from the chart.

This is the most criticxal decision you must make.

An overcharge can blow up nthe gun and injure the shooter

or persons nearby. It is dangerous to use a bullet of a

greater weight with a charge for a lighter bullet.

Never select a load intended for a bullet lighter

than you are using.

Loads for a slightly heavier bullet are safe.

Always start with the Starting Loads.

You maay work up to the Never Exceed Loads gradually,

provided you know how to watch for pressure signs.

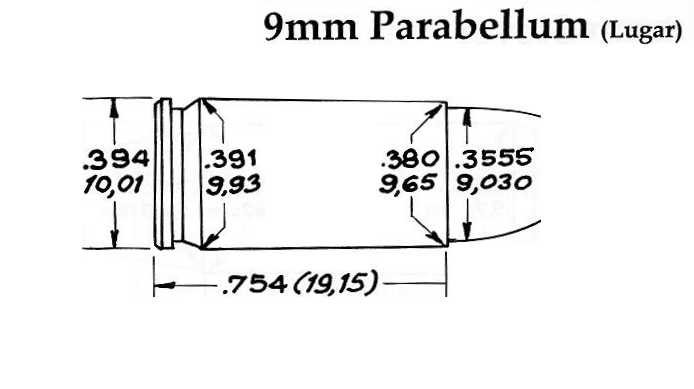

a couple examples from the load sheet:

HP-38 Hogdgon Pistol Powder

9mm 115gr Jacketed Bullet

Start: 4.7gr 1081fps

Do Not Exceed: 5.1gr 1167fps

9mm 124gr Jacketed Bullet

Start: 4.4gr 1008fps

Do Not Exceed: 4.8gr 1088fps

5. Bullet Seating Die

Raise the ram to the top of its stroke and hold.

Screw the bullet seating die in until it touches the shell holder.

Then back it out three full turns.

Lightly finger tighten the lock ring.

Bullet depth is adjusted by screwing the adjusting screw in

or out to suit.

Bullets should be seated deep enough to work thru the guns action.

See Maximum Overall Length on the charge table.

6. Factory Crimp Die

The Lee Carbide Factory Crimper will not seat the bullet.

The bullet should be seated with a regulat bullet seating die,

but not crimped (some seating dies can be adjusted to place

a crimp as the bullet is seated).

Bullets should normally be seated so the crimp groove (cannelure)

is mostly inside the case mouth.

Screw the die in until it just touches teh shell holder and back

out the adjusting screw. Finger tighten the lock ring.

Always remove the die by turning on the lock ring to loosen.

With the loaded round in the die, turn the adjusting screw in

until you can feel it just touch the case mouth.

Then move the cartridge out of the die slightly and screw the

adjusting screw in 1/2 turn for a light crimp and

one full turn for a heavy crimp.

Some flaring dies can be adjusted to provide too much flare

and the case will not enter the crimp die. Try using the

sizing die to close the flare.

The carbide ring will size the brass when entering and upon

exit of the die. This assures that every case will freely

chamber in any standard firearm.

Do not expect the carbide sizer to touch every case,

it is a fail safe for the occasional bad round.

| | |

| |